Ball Valve

Ball Valve Specification

- Structure

- Ball

- Connection

- Screwed, Flanged

- Channels

- Two Way

- Pressure

- PN16 to PN40

- Caliber

- Full Bore

- Material

- Stainless Steel

- Power

- Manual

- Media

- Water, Oil, Gas

- Port Size

- 1/2 Inch to 4 Inch

- Flange

- ANSI/DIN Standard

- Finish

- Polished

- Application

- Industrial, Plumbing, Chemical Processing

Ball Valve Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- Piece

- Delivery Time

- as per Week

About Ball Valve

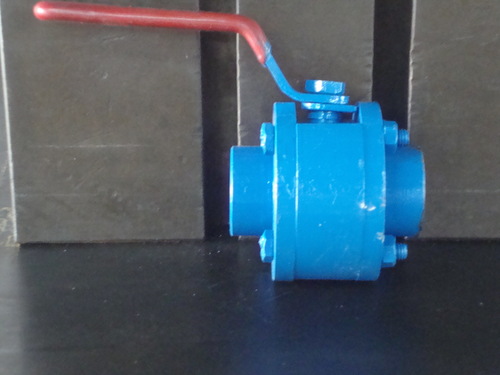

Ball Valve

Clients can avail from us a very sophisticated variety of Ball Valve that we design and develop from quality corrosion resistant material derived from trusted vendors. These valves are commonly used for handling slurries, viscous & sticky fluids and highly corrosive substances in different industries like petrochemical, pharmaceutical and textile. Suitable for controlling complex materials, our offered Ball Valve is easy to use and can maintain high volume, high pressure and high flow of temperature.

Product Details:

| Condition | New |

| Application | Petrochemical, Pharmaceutical And Textile |

| Usage | Handling Slurries, Viscous And Sticky Fluids etc |

| Color | Blue And Red |

Superior Durability and Longevity

Designed to withstand up to 100,000 operating cycles, this ball valve offers exceptional longevity for demanding industrial environments. Stainless steel construction and high-grade PTFE seals guarantee resistance to wear and corrosion, minimizing maintenance requirements and extending service intervals.

Precision Engineering for Seamless Control

A quarter-turn lever handle allows for swift and precise flow regulation. The full bore, two-way channel structure minimizes pressure drop, while rigorous testing to API 598 ensures dependable shutoff and system integrity under pressure.

Versatile Installation Options

Available in one, two, or three-piece body types with both threaded and flanged connections, the valve adapts easily to various piping standards, including ANSI and DIN. Port sizes range from 1/2 inch to 4 inch, making it highly versatile for different system requirements.

FAQs of Ball Valve:

Q: How is the ball valve operated and what type of handle does it use?

A: This ball valve is manually operated using a quarter-turn lever handle, enabling easy and precise open or close action with a simple 90-degree rotation.Q: What types of fluids and industrial applications is this valve suitable for?

A: The valve is engineered for a wide range of fluids such as air, gas, oil, water, and steam, making it ideal for industrial, plumbing, and chemical processing applications.Q: What testing standards and pressure ratings does this valve meet?

A: It conforms to the API 598 testing standard, undergoes a body pressure test at 1.5 MPa, and a seat pressure test at 1.1 MPa. The valve operates reliably within pressure ranges from PN16 to PN40.Q: When should a flanged end be selected over a threaded end?

A: Flanged ends are recommended for higher pressure, larger-diameter piping, or where more secure, rigid connections are needed. Threaded ends suit smaller-diameter, lower-pressure systems requiring ease of installation or maintenance.Q: Where is this ball valve manufactured and to which standards does it adhere?

A: Manufactured in India, the valve meets ANSI and DIN flange standards, confirming its suitability for international and diverse industrial systems.Q: What are the benefits of the PTFE seal material and stainless steel body?

A: PTFE seals provide excellent chemical resistance and low friction, ensuring leak-tight performance. The stainless steel body enhances the valves strength, corrosion resistance, and longevity in demanding environments.Q: How does the full bore, two-way channel design improve valve performance?

A: A full bore allows unrestricted flow, minimizing pressure drops, while the two-way channel structure supports bidirectional flow for greater system flexibility and efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS