Valves

Valves Specification

- Material

- Forged Brass, Stainless Steel, Cast Iron, PVC

- Control System

- Manual, Electric Actuator, Pneumatic Control

- Features

- Corrosion resistant, leak proof, durable, easy installation

- Connection Type

- Flanged, Screwed, Socket Welded

- Valve Type

- Industrial Valves

- Valve Size

- DN15 to DN150

- Sealing

- PTFE, EPDM, or NBR

- Voltage

- 24V AC/DC, 220V AC

- Application

- Industrial fluid control, water, oil, gas, steam regulation

- Type

- Ball Valve, Gate Valve, Globe Valve, Butterfly Valve

- Power

- Manual or pneumatic/actuator operated

- Pressure

- Up to 16 Bar

- Media

- Water, Oil, Air, Gas, Steam

- Port Size

- 1/2 inch to 6 inch

- Disc

- Stainless Steel/Brass/Cast Iron

- Pin

- Metal alloy

Valves Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- Piece

- Delivery Time

- as per the quintity Week

About Valves

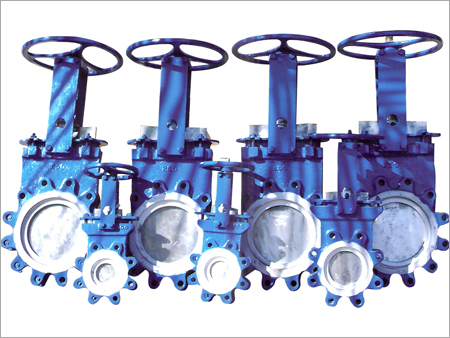

Valves

Owing to our experience and skills in this market, we have been successfully engaged in manufacturing and supplying wide range of Valves. These products are used in different industries like petrochemical, pharmaceutical and engineering to sustain flow of high volume, high pressure and high temperature. The salient features of our Valves are robust design, excellent performance and longer service life. Designed and developed with precision and care, these products are available in different sizes and end connections.

Further Details

"Knife Edge Gate Valves are suitable for media applications like abrasive slurry lines, Pulp lines etc. And are available different material of constructions like Cast iron, Cast steel & Stainless steel Bodies and in SS-304, SS-316, SS-316L, Stellited gates along with deflection cones. The knife edge gate valves will be hand wheel. Operated, pneumatic actuator operated, Electric actuator operated type".

Product Details:

| Available Material | Cast Iron, Cast Steel And Stainless Steel |

| Condition | New |

| Color | Blue |

| Usage | Petrochemical, Pharmaceutical And Engineering |

Precision Engineering and Standards

Our valves are manufactured to comply with ISO, DIN, and ANSI standards, ensuring global quality and reliability. This adherence allows seamless integration into industrial processes and guarantees consistent performance backed by stringent testing, including pressure tests at 1.5 times working pressure.

Versatile Applications and Control

Suitable for controlling water, oil, air, gas, and steam, these valves are ideal for industrial fluid regulation. With options for manual, electric actuator, or pneumatic control, users can select the right system for precise flow and pressure management. The available port sizes and connection types fit diverse installation requirements.

Durability and Easy Maintenance

Made from corrosion-resistant materials such as stainless steel, forged brass, PVC, and cast iron, our valves are designed for longevity and leak-proof operation. Their polished or coated surface finish simplifies cleaning and maintenance, while robust sealing (PTFE, EPDM, NBR) ensures excellent performance over time.

FAQs of Valves:

Q: How do I choose the right valve type for my fluid control application?

A: Select the valve based on the media type (water, oil, gas, steam), connection requirements (threaded, flanged, welded), and control needs (manual, electric, pneumatic). Ball, gate, globe, and butterfly valves each provide distinct advantages for regulation and shut-off functions.Q: What benefits do polished or coated surface finishes provide on these industrial valves?

A: Polished or coated finishes offer superior corrosion resistance, minimize surface wear, and facilitate easier cleaning. This enhances the valves durability and sustains leak-proof operation in demanding industrial environments.Q: When is actuator mounting with ISO 5211 pad recommended?

A: ISO 5211 pad mounting is ideal when automated or remote valve operation is needed, such as in systems requiring integration with electric or pneumatic actuators. It standardizes actuator installation across various valve sizes and types.Q: Where can these valves be installed?

A: These valves are designed for use in industrial settings, suitable for water treatment plants, oil refineries, chemical processing, and gas regulation systems. The multiple connection types ensure adaptability to diverse piping configurations.Q: What is the process for valve testing and ensuring leak-proof performance?

A: Each valve undergoes rigorous pressure testing at 1.5 times the working pressure to guarantee leak-proof integrity and operational reliability, meeting ISO, DIN, and ANSI standards.Q: How does low torque operation influence valve usage and safety?

A: Low torque operation allows for easier manual or automated actuation, minimizing operator effort, reducing wear on handle and actuator components, and improving safety during operation.Q: What are the advantages of using valves with multiple sealing options such as PTFE, EPDM, or NBR?

A: Having multiple sealing material options ensures compatibility with different media and operating conditions. PTFE is suited for high temperature and chemical resistance, EPDM for water and steam, and NBR for oils and gases.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Valves Category

Fire Hydrant

Minimum Order Quantity : 1 Piece

Application : Fire Safety, Emergency Water Supply

Port Size : 63 mm (Typical)

Valve Size : 63 mm/80 mm (Common Sizes)

Media : Water

Type : Outdoor/Indoor Hydrant

Tee Strainer

Minimum Order Quantity : 1 Piece

Application : Filtration of foreign particles from pipelines in water, oil, steam, and gas applications

Port Size : 1/2 inch to 24 inch

Valve Size : DN15 to DN600

Media : Other, Water, Oil, Steam, Gas

Type : Tee Strainer

Constant Oil Leveler

Minimum Order Quantity : 1 Piece

Application : Maintaining constant oil level in bearing housings and gearboxes

Port Size : 1/2 BSP (standard); available up to 2 BSP

Valve Size : Standard up to 2 BSP

Media : Other, Lubricating oil

Type : Float operated constant level oiler

Filter Elements For Strainers

Minimum Order Quantity : 1 Piece

Application : Filtration of liquids and gases in pipelines

Port Size : Customizable as per strainer design

Valve Size : To suit strainer body

Media : Other, Water, Oil, Gas, Chemicals

Type : Filter Element

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS