Non Return Valve Reflux Type

Non Return Valve Reflux Type Specification

- Control System

- Manual (automatic flow control, no actuator)

- Material

- Cast Iron, Cast Steel, Ductile Iron

- Connection Type

- Flanged end, conforms to IS standards

- Valve Type

- Check Valve

- Valve Size

- 2 inches to 24 inches

- Application

- Industrial fluid handling, water supply, pipeline systems

- Structure

- Swing type, reflux type mechanism

- Type

- Non Return Valve Reflux Type

- Pressure

- Up to PN16

- Media

- Water, oil, gas, steam

- Port Size

- Available from 50 mm to 600 mm

- Disc

- Single flap (swing type disc)

Non Return Valve Reflux Type Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- Piece

- Delivery Time

- as per the quintity Week

About Non Return Valve Reflux Type

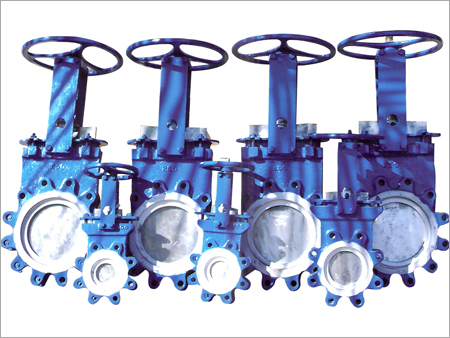

Non Return Valve Reflux Type

For over 17 years, we are incorporated as a manufacturer of one of the most extensive lines of high performance Non Return Valve Reflux Type. Available in different end connections and different port openings, these non return valves gives excellent performance. We are using supreme quality cast steel, stainless steel and cast iron in manufacturing of these valves. Our Non Return Valve Reflux Type is widely used in pharmaceutical, distillery factories and paper mills for various applications.

Further Details

Non Return Valve are available different material of constructions like Cast iron, Cast steel & Stainless steel Bodies and in SS-304, SS-316, SS-316L, Stellited gates along with deflection cones. The knife edge gate valves will be hand wheel. Operated, pneumatic actuator operated, Electric actuator operated type.

Product Details:

| Available Material | Cast iron, Cast steel And Stainless steel |

| Used In | Pharmaceutical, Distillery Factories And Paper Mills |

| Condition | New |

| Color | Blue |

Versatile Design and Reliable Performance

The Non Return Valve Reflux Type is carefully engineered to prevent reverse flow across a wide range of industrial applications. Its swing-type structure and automatic operation ensure fluid only moves in the intended direction. With compatibility for various pipeline sizes and pressure conditions, it delivers dependable service for water, chemical liquids, oil, gas, and steam systems. Full-bore body construction guarantees minimal head loss and energy efficiency.

Simplified Installation and Maintenance

This valve supports both horizontal and vertical installations and features standard flanged ends that comply with Indian and British codes. The bolted cover enables straightforward inspection and maintenance, minimizing downtime. Manual operation with automatic flow control ensures ease of use without external actuators. Its robust construction ensures longevity and adaptability for multiple industries.

Built for Durability and Compatibility

Constructed with high-quality Cast Iron, Ductile Iron, or Cast Steel, and offering seat options in EPDM, Nitrile, or metal, the reflux-type valve is designed for harsh operating conditions. Gasket materials in rubber or PTFE further enhance resistance to chemicals and wear. Hydraulically tested to IS/BS standards, the valve ensures safety and performance integrity for all supported media and applications.

FAQs of Non Return Valve Reflux Type:

Q: How is the Non Return Valve Reflux Type installed in a pipeline?

A: The Non Return Valve Reflux Type can be installed in either horizontal or vertical pipelines. It comes with standard flanged ends as per IS codes, allowing easy connection to most pipeline systems. Proper alignment and securing of the flanges with bolts are essential to ensure leak-free operation and optimal performance.Q: What types of media are suitable for this check valve?

A: This valve is engineered to handle a wide range of fluids, including clear water, sewage, chemical liquids, oil, gas, and steam. Its seat and gasket material options, such as EPDM, Nitrile, rubber, and PTFE, make it adaptable for various industrial applications.Q: When should I use a reflux type non-return valve in my system?

A: Reflux type non-return valves are essential when preventing backflow is critical in fluid handling systems. They are ideal for applications in water supply, industrial pipelines, sewage systems, and chemical processing plants, especially where reverse flow can cause system contamination, damage, or inefficiency.Q: Where can this valve be applied within industrial facilities?

A: This valve is suitable for installation in water and wastewater treatment plants, industrial process pipelines, pumping stations, and chemical distribution systems. Its robust design makes it applicable wherever reliable backflow prevention is required.Q: What is the process for maintaining the valve?

A: Maintenance is straightforward due to the bolted cover design. Regular inspection involves unbolting the cover to check the integrity of the disc, seat, and gaskets. Cleaning and replacement of worn components can be performed easily, minimizing downtime and ensuring continued performance.Q: How does the valve offer automatic flow control without an actuator?

A: The valve utilizes a swing-type single flap disc that automatically opens when fluid flows in the correct direction and closes when flow reverses. This mechanical action requires no external actuators or manual intervention after installation, providing reliable and automatic operation.Q: What benefits does the full bore design provide?

A: The full bore design ensures minimal head loss and maintains high flow efficiency. It reduces turbulence and energy consumption within the pipeline, making it an energy-efficient solution for systems handling large volumes of fluid.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Valves Category

Valves

Minimum Order Quantity : 1 Piece

Valve Size : DN15 to DN150

Port Size : 1/2 inch to 6 inch

Connection Type : Flanged, Screwed, Socket Welded

Media : Other, Water, Oil, Air, Gas, Steam

Valve Type : Industrial Valves

Constant Oil Leveler

Minimum Order Quantity : 1 Piece

Valve Size : Standard up to 2 BSP

Port Size : 1/2 BSP (standard); available up to 2 BSP

Connection Type : Threaded (BSP/NPT)

Media : Other, Lubricating oil

Valve Type : Oil level maintaining valve

Y Strainer BIG

Minimum Order Quantity : 1 Piece

Valve Size : Big (Standard large sizes available to suit pipeline)

Port Size : 3 inch (can vary as per requirements)

Connection Type : Flanged End (standard), can be customized to Screwed Ends

Media : Other, Water, Oil, Gas, Steam

Valve Type : Y Strainer

Duplex Strainers

Minimum Order Quantity : 1 Piece

Valve Size : As per port size

Port Size : 1/2 to 24 or as per requirement

Connection Type : Flanged or Screwed End

Media : Other, Liquids and Gases

Valve Type : Changeover Valve

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS